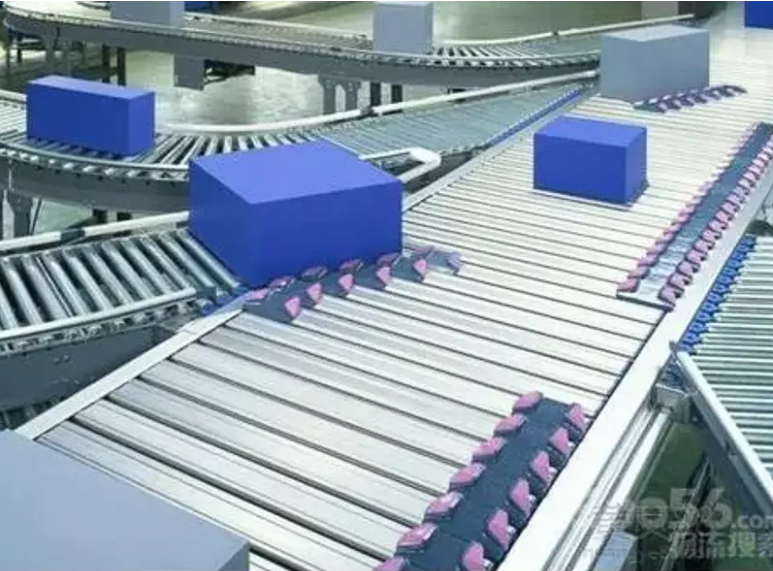

How Does The Sorting Line Work

Time:

24 Nov,2022

The current logistics sorting has made great progress, and is also at the forefront of some technology, but some of the steps are still dependent on manual; logistics sorting is a relatively important part of logistics, sorting means that the items are sorted according to different specifications, the current process of warehouse logistics sorting is still relatively advanced, on this issue Limin Technology to explain some intelligent logistics sorting line some of the What are the steps? As well as some necessary knowledge, smart logistics is a way to reduce the error rate and is faster.

1. Picking task arrangement

The design of the sorted items is based on two principles.

A. Single goods orders are handled separately

Single goods orders in the scan out of the warehouse can be taken in a different way from ordinary orders (specific practices are described later when it comes to scanning shipments), can significantly improve the speed of scanning out of the warehouse, and therefore need to be handled separately.

B. Large partition of orders, small aggregation

The advantage of the seeding method is aggregation, where multiple orders are processed together and the picker only has to go through the picking path once to complete the picking of all orders.

However, as mentioned earlier, due to various restrictions, picking batches are generally limited to 50 orders, which does not guarantee a random and even distribution of goods in the warehouse. Instead, it is likely that some of the goods are at one end of the warehouse, while another part of the goods are at the other end of the warehouse, so that the entire picking path will be lengthened, and picking staff will have to walk a lot more, affecting the picking efficiency.

The more ideal situation in picking is to complete the picking of all goods in one bay, but this is obviously impossible, then in this idea, the concept of replacing a bay with a smaller area in which the picking of all orders is completed, its efficiency will also be higher.

Therefore, the entire warehouse is broken down into several areas, and when assigning picking batches, try to select orders that are all located in a certain area or in several adjacent areas to form a picking batch. In this way, small aggregations are achieved in large partitions, which can lead to more efficient picking.

In the case of more data support, but also in the allocation of inventory location, consciously will be the customer at the same time to buy a higher probability of several pieces of goods placed in the same area, which will make the "small aggregation" more closely.

2. Picking path planning

The planning of picking paths is actually the path planning problem in geoinformatics, which will not be discussed in this paper. The path planning operation in the logistics warehouse is based on the goods level information, the geometric order of the goods can be distinguished according to their location, so it can also be based on the goods level number sorting, the development of path planning rules (i.e., the rules of the goods level sorting), so as to get the picking path.

When the same goods are in stock in multiple bays, the picking task is assigned, often comparing all possible picking paths (provided that all bays are adequately stocked), and then selecting the better path of them. The calculation logic is more complicated when there is insufficient quantity of stock on some bays, which will not be described here.

3. Picking task execution

The execution of the picking task, i.e. the process of picking out goods from the goods position, requires attention to two points: the correct goods picked and the correct quantity of goods.

The operation is usually handled directly by the picker manually, but for the operation. . To reduce errors, all manual operations should correspond to the system. The ideal way is to use RF devices to scan barcodes one by one to confirm that the goods and quantities are correct. However, when scanning one by one, the efficiency will be affected, so sometimes only one item is scanned to pick and check the correctness of the goods, while the quantity check is done by manual.

4. Sorting

The seeding method requires a picking process after the picking batch is completed in order to break the batch pick into individual orders. The sorting process is roughly the same as scanning first, then the system prompts which order corresponds to which compartment on the sorting shelf, nothing special from the system's point of view. In operational production, give more thought to the details of.

The font displayed on the computer screen should be large enough, so that it is convenient for the operator to identify; B. The scan gun is better supported by a stand, which can free the operator's hand to improve production efficiency;

How to arrange the relative positions of sorting racks, picking trucks, operators and workstations in order to ensure both efficiency and ease of batch flow.

Logistics is what we can't live without, the daily work of sending and receiving courier sites are also busier every day, and e-commerce is also more important, the price is cheap and easy to find what you need.

2022-11-24 | Limin Group

Share to

freya.ren@limin-global.com

freya.ren@limin-global.com

0086-15093376710

0086-15093376710